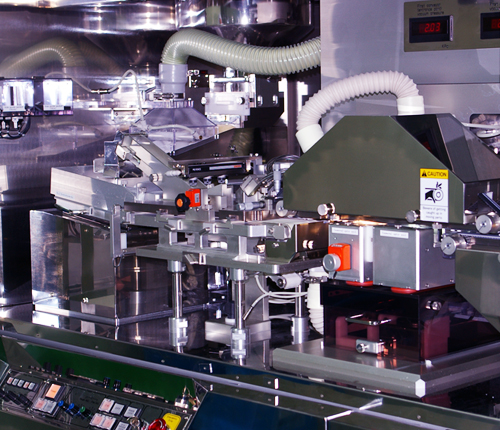

Medicines should keep high quality as they are directly related to people’s lives. To produce such important medicines, clean water and air are considered as the most fundamental factors.

All the products of Daewon Pharm are produced by advanced water processing and air conditioning systems.

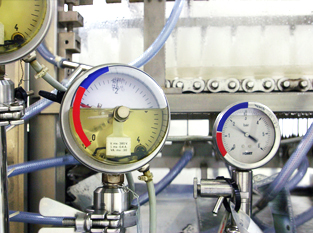

The water used in manufacturing products is highly purified at the level of cCMP, which is processed with water processing system including activated charcoal and reverse osmosis (RO) filters.

And then, clean pipes carry this purified water to each production line. Air is also purified with multiple steps of filters, carried through heating and cooling systems, and supplied to all production lines.

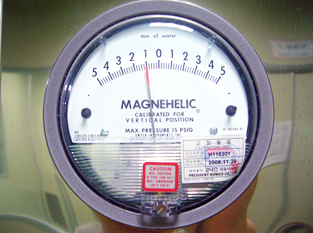

The air quality inside factory is divided into 100 to 100,000 classes depending on region to manage it at the level of cCMP.

To avoid cross-contamination, the automatic air density and pressure control system is operated to prevent dust inside the working space from being pushed outward.

In addition, the automatic temperature control system is helpful to maintain a certain temperature inside the factory.

As for validation to guarantee a perfect quality, the most important factor is documents.

Daewon Pharm is recording all validation documents required by cCMP including measuring instrument inspection and calibration, facility competence evaluation, process validation by product, and test method validation. These documents are also systematically maintained following relevant regulations.